Product Realization of 3D Tic-Tac-Toe Game Box

Four colleagues and I manufactured a product of our choice within a given budget of $10 per product. During the product development process, we used the same industry practice of manufacturing stages which included prototyping, EVT, DVT, PVT, and MP as well as generating product and process documents. Some of the finalized documentations can be found at the following links: Specifications, Risk Analysis, dFMEA, Bill of Materials (BOM), Quality Test Plan, and SOP.

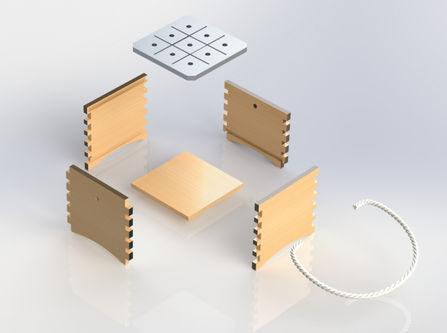

Concept Design

Our final concept of the 3D tic-tac-toe game box is shown below. It will implement game pieces of different colors and shapes that stack on top of each other,. The pieces will be stored in the box by sliding the board out of the top. Rope handle will be sourced for carrying purposes. This design will offer a unique interaction with a classic tic-tac-toe game, adding another dimension of fun. We think that the puzzle piece box will allow for ease in assembly and the stacked pieces minimizes the amount of different parts we have to manufacture.

During this stage, we began writing the specifications document, BOM, cost model, and the required tooling. 3D renderings and 2D drawings of the design are shown below.

Initial Prototype

The final rendering of the prototype and the physical prototype are shown below. Changes were made from the previous design to ease the manufacturing process:

-

Slots at the top of the sides were modified to be through-all.

-

Bottom of the box changed to be flat, instead of arched.

For the physical prototype, the box was made out of plywood made using a table saw; the game board is an acrylic that has been laser cut; and the game pieces were 3D-printed on a FDM printer. Fourteen of the game pieces fit inside the box with ample space, and so, we concluded that 27 game pieces will fit inside.

What Worked

-

Aesthetics

-

Box and finger joint size as desired

-

Pieces shape and size as desired

-

Acrylic board

-

Cracking on edges, etching/coloring of crosses didn't come out as expected

-

-

-

Functionality

-

Board slides smoothly in wooden slots

-

Finger joints fit well

-

Pieces stack and fit nicely

-

Back board slot may not be needed for board to cover top completely

-

-

Manufacturing

-

Cut slots before cutting individual box pieces

-

Align with grain for finger joints

-

Crucial that individual pieces have flat edges for slots to line up

-

Laser cutting acrylic settings needs more refining

-

Next Steps

-

Make a new jig

-

Current one does not have a flat fixture

-

-

Standardize wood-cutting methods

-

Standardize procedures to ensure that panels have flat, straight edges

-

-

Experiment with laser cutter

-

Test different settings to prevent acrylic cracking

-

-

Cast the pieces

-

Begin testing best method for to casting the pieces

-

Manufacture necessary molds

-

Engineering Validation Testing (EVT)

The EVT stage focused on refining the manufacturing processes, crafting a quality test plan, and continuing to update cost and risk models. This stage was interrupted by the COVID-19 global pandemic. As a result, the manufacturing plans were not able to be completed with the newly revised manufacturing processes. A jig was created to manufacture the teeth on box sides, but the jig was unable to be used before manufacturing facility was closed. A mold was created based on the new 3D printed pieces, and a casting of each piece was done. A tooling plan was created to outline the different tools needed and steps that are involved. Tolerance analysis was conducted on the box sides from the concept stage and defect analysis was conducted on the casted pieces. The pieces were redesigned with a focus of DFM. Images of the final rendering and the casted game pieces are shown below.

Design Validation Testing (DVT)

The DVT stage focused on verifying the design of our product with the manufacturing process that we have selected. A control plan and process plan were created. It was decided that the wooden box pieces would be manufactured in house and the game pieces and acrylic board lid would be outsourced. The tooling plan was reevaluated for mass production based on the process plans created with production techniques chosen for each component. The total tooling needed was estimated to be around $100,000 which could be reduced further with mold redesigning and further capital capacity analysis. A packaging concept was developed with potential materials chosen and cost. The BOM and cost model were updated for mass production techniques and to include packaging. The total COG estimated is $5.50. All previous documents were updated including tolerance analysis, specification, risk, and quality test plan.

Packaging

A plastic box will be used for packaging the game box, as shown below. The bottom half of the packaging will have information about the game printed. There will be 8 paper corner inserts to hold the box in place, and the instruction manual on how to play the game will also be included in the packaging. The game pieces will be packaged in their own packaging bags.

Mass Production (MP)

Since we do not have the capability to mass produce our product, we have developed a theoretical plan for MP. We used Flexsim to simulate the manufacturing process in mass production mode, and aPriori to estimate the cost.

-

Game pieces: outsourced - injection molded

-

Board/lid: outsourced - laser cut

-

Rope handle: outsourced

-

Wooden box: in-house

-

Cut into smaller panels (table saw)

-

Slots cut in panels (table saw)

-

Finger joints cut (finger joint machine)

-

Market Analysis & Cash Flow

-

Target Audience: 12+

-

Intended Sales Price: $29.99

-

Initial Production Quantity: 1,000

-

Break-even point: 29 months

Key Potential Risks

-

Game pieces

-

Twisted piece showed potential plastic issues in aPriori

-

Account for most of COGs

-

Redesign sizing to reduce cost

-

-

-

Manufacturing

-

Finger joint machine

-

If wood panels are not square, cut will be off

-

-

No post-processing of wood

-

Need for potential sanding to reduce splintering

-

Could decrease durability and lifespan of wood

-

-

Table saw cutting: need for high skilled labor

-

High risk for potential injury

-

-

-

Issues with rope ripping

-

Wood may rip through rope with constant rubbing

-

Project Findings

-

Game pieces

-

Had to find balance between aesthetic, cost, and feasibility of manufacturing

-

-

Manufacturing

-

Finger joint machine facilitated the assembly of the box

-

Created a better more consistent fitting of box pieces

-

Reduced the need for a seperate jig

-

-

-

Costing parts early can help facilitate design changes

-

Small size reduction results in large price savings

-

-

Prototype early and often

-

Best way to discover issues with initial concepts

-

Able to discover problems with design of pieces fit

-

Box dimensions changed after prototyping finger joints

-

-